| pudg | 04-27-2010 | comment profile send pm notify |

|

well is this a trick question ? but usually on the twin wall there is a tag,and there is two linings,the part about a rip or tear is you never know if that one pipe was mismatched I would check the entire line either hammer check or get you one of those pipe thickness testers,when I replace pipe I like to do the whole pipeline,and never mismatch esser or any other twinwall with just regular heat treated pipe it will work fine at first until the wear starts and then you will start getting buildup ,something I learned unwillingly from a manufacturer that decided to put esser twinwall pipe but just heat treated 90s. |

||

| rick5z | 04-27-2010 | reply profile send pm notify |

|

they make a sonic tester i dont know where you can get one but someone on here will, also if one pipe is worn out its a pretty good sign that all of it is shot |

||

| biged | 04-27-2010 | reply profile send pm notify |

|

Whats wrong with lighty grinding off the paint, just asking. |

||

| bisley57 | 04-27-2010 | reply profile send pm notify |

|

Look at the ends,you will see the inner liner.Use the stuff that Putz uses,the deck pipe goes ding.......... |

||

| Boom Inspector | 04-27-2010 | reply profile send pm notify |

|

Yea Biged, grinding works but then I spend even more time repairing the paint job. @Bisley, thats pretty much what i did but the customer wanted more info i guess.I just was wondering how most operators decided when it was time to change the system. |

||

| JDR47 | 04-27-2010 | reply profile send pm notify |

|

Tap the pipe with a hammer, ding is good pipe. If it goes donk then change it. Look at Con Forms they have boom and deck kits in a crate. |

||

| Drew AUS | 04-27-2010 | reply profile send pm notify |

|

Ultra sonic testers are uslass on twin wall pipes, paint or not they only pic up the outer layer not the inner! the outer layer of a twin wall is roughly 3mm , Verneer calipers are good for twin wall also. Use the thickness tester to get you outer layer the the calipers to get the whole amount then minus the outer layer and bingo !!!!!! You have your inner wall thickness

|

||

| TRKDOC | 04-27-2010 | reply profile send pm notify |

|

Hello Boom Inspector! Con forms is a good source for replacement pipe. Twin wall pipe, to my knowledge, cannot be accurately measured with a meter. We used an electronic meter that resembles a multi-meter that has a magnetic probe. By using a piece of emery cloth, we sanded a piece of the pipe about the size of a quarter near the end of the pipe by the flange. Pipe seems to wear the quickest in this area. We recorded the thickness of the pipe by writing on the pipe with a sharpie so that the operator could keep an eye on what was going on. We checked pipe 3 or 4 times a year on each machine. Pipe thinner than .90 was considered marginal. I agree that paint sanded off the pipes does not look good, but this method allows anyone who would look the opportunity to see that the pipes have been checked. In the event of a blow-out, it is obvious that the operator and the company have used due care. Typically, it is a good idea to replace pipe a boom section at a time at least. Worn pipe next to new pipe will wear out the new pipe faster! Hope this helps....I am no expert on pipe, but this method worked well for us! |

||

| ezconcretepumper | 04-28-2010 | reply profile send pm notify |

|

I used to run a 98 putz. 36 m. We put brand new pipe on it and the 1st piece to go was on the 3rd stage last piece b4 the elbows just after the crossover. So I say no. Just the design of the pump. Was able to change the pipe and turn every so often and get many more yards pumped through the rest of the pipe. Hope this helps. |

||

| Many | 04-28-2010 | reply profile send pm notify |

|

When one pumps the guts out you have twin wall |

||

| TooTall | 04-28-2010 | reply profile send pm notify |

|

For doG sake dont beat on it! Just tap it lightly with the handle of the hammer not the Head. The interior very brittle and WILL crack or break. You can't always identify dual wall just by looking at the ends. Some pipes have carbite inserts that are only on the ends. I dont remember exactly what letters to look for but both CF & Esserwork dual wall pipes are stamped with an ID. Sonometers dont work for guaging wall thickness on dual wall for the very same reason they dont "Ding", even a new one will "sound" like it's wore out >"clunk"<. The only way to know exactly is to weigh them to see just how worn they are over all. Like Bisley said some pipes wear faster on different machines and depending where they're located in the system. For example, the pipe on the main (B) section is going to wear more on the bottom or compression side. Pipe on the tip section tends to wear more evenly since it's generally in a vertical position more often then being horzontal when it's stretched out... It all depends on the boom configuration etc. Here's a pic of a dual wall, since it's now a fence post and full o hard concrete you cant tell if it's a dual wall or just has carbite inserts... |

||

| TooTall | 04-28-2010 | reply profile send pm notify |

|

Here's a better one... The red arrows mark the ring to look for on the end of the flange. The yellow arrows point out that's it's not a dual wall pipe it just has inserts on the ends. Pay no attention to the little man inside, he's my pipe inspector... |

||

| TooTall | 04-28-2010 | reply profile send pm notify |

|

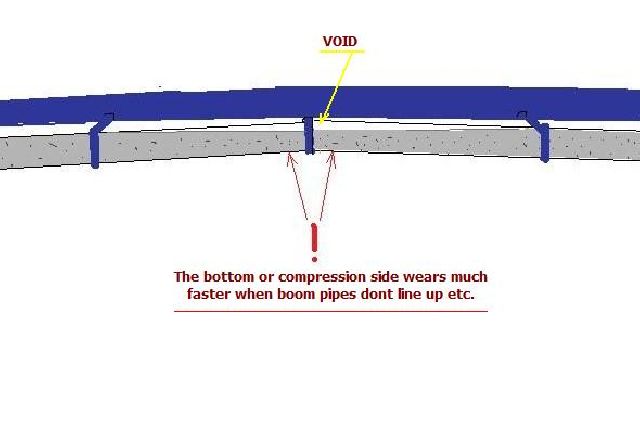

Here's one more thing to keep in mind... On lazier sections that have a tendancy to sag, like the tip, 3rd & 4th, especially on longer booms. When they're stretched out and loaded this can cause the pipes to not line up since they don't flex or sag like the the section they're attached to. Like so... |

||

| TooTall | 04-28-2010 | reply profile send pm notify |

|

Rotating the boom pipe 180 degrees in these problem areas on a regular basis allows them to wear more evenly and they'll last longer. I like to rotate the pipes on the tip section and the pass over on the 3rd every 10K yds. or so. I've blown more pass over pipes (The same one Bisley was talking about) than I care to admit! |

||

| wnichols | 04-28-2010 | reply profile send pm notify |

|

To my knowledge there are no 100% accurate sonic testers on the market that will measure twin wall pipe from the outside without you drilling a small hole in the outer pipe. We tried this at Esser about 3-4 years ago and it wasn't enough to only have one hole per pipe due to the fact that a pipe will wear in different areas for many different reasons.

If you need pipe for your Schwing pumps you can contact me directly and I would be happy to give you a quote and help you fit the pipe system to your needs. |

||

| TooTall | 04-28-2010 | reply profile send pm notify |

|

Just do like I do Boomin Spector. Imagine yourself being pumped through the system. Then think where you'll get slammed into the pipe wall the hardest and which of those will hurt the most... There's your critcal wear points. Be One with the concrete. |

||

| wnichols | 04-28-2010 | reply profile send pm notify |

|

Identification of our pipe (Esser) and other manufacturers pipe is relatively easy. In the recent past we have used a metal tag on the outside of all pipe and elbows (where possible) that has a part number and our company name stamped/embossed in the tag.

Each pipe should also have the working pressure and the rated burst pressure as well on the tags.

As for telling the difference between single wall and twin wall...well that gets a little more complicated. Esser has not had a single wall boom pipe up until now. We are just bringing our single wall boom pipe into the market this month and have only had a twin wall pipe available. Other manufacturers with single wall pipe you need to look at their tags to get the part numbers and then contact them to see if the pipe was single wall or twin wall. I can help with that as well if you need it.

Any other questions don't hesitate to drop me a PM or a question here on the board. |

||

| wnichols | 04-28-2010 | reply profile send pm notify |

|

TooTall nailed it on the head...DON'T BANG ON PIPE to clear the blockage...unless you are ready to replace the system in a few days/weeks. |

||

| typesdubs | 04-28-2010 | reply profile send pm notify |

|

Hey Esser how come you are making single wall pipe now? |

||

| wnichols | 04-30-2010 | reply profile send pm notify |

|

From my side I have always thought that the single wall from CF was good for what it was...a low cost entry level product to the end user and have thought that we needed a similar product.

|

||

.jpg)

.gif)

.jpg)

.jpg)