| Todd | 12-11-2017 | comment profile send pm notify |

|

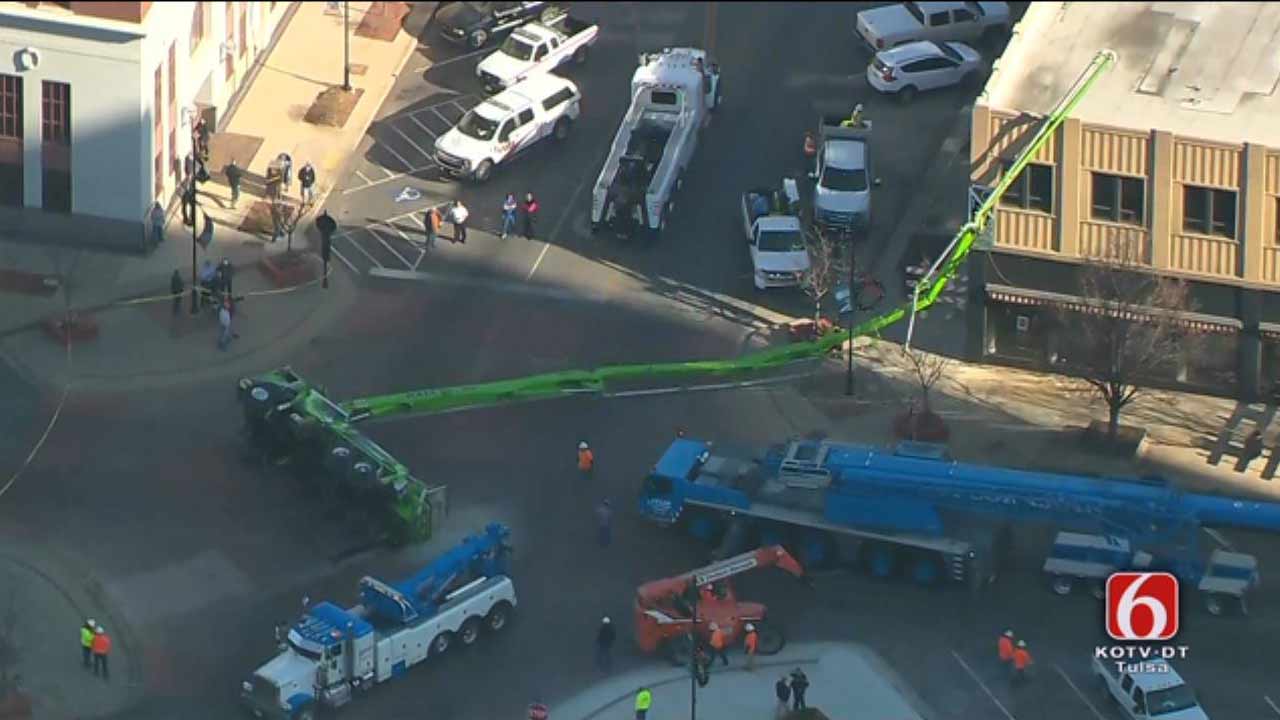

BARTLESVILLE — A downtown intersection was closed after construction vehicle fell over and damaged a building on Monday, police said. Shortly before noon, a concrete extension boom truck fell over and caused damage to a building at Johnstone Avenue and Frank Phillips Boulevard in downtown Bartlesville, Bartlesville police Capt. Jay Hastings said in a news release. "Apparently the driver finished a job and began to move the truck with the boom still extended, causing the truck to tip over. Fortunately the driver and no one on the ground were injured," the release said. Crews will be working to turn the truck over and clean up the area. The driver revived a citation for failure to secure load, police said. |

||

| bisley57 | 12-13-2017 | reply profile send pm notify |

|

Thats the problem with this industry,your local favorite pump company sends a 61 mtr to a job with 1 operator who has to build mats with freakin 2x12s by himself,yet a crane rental company sends out a mobile crane , and brings a forklift to set proper outrigger pads with 3 or 4 laborers to help.Son of a bitch,there wasnt 1 mammy set of eyes and ears watching this poor operator and tell him he was doing wrong.The construction super and everyone near that pump should be wearing a dunce cap for the next month.Yes,the operator messed up,but management is the bunch of screwballs.Maybe the ACPA will do something worthwhile besides sponsoring booty parties, sad I do realize that was not a 61 |

||

| Farmer Joe | 12-13-2017 | reply profile send pm notify |

|

We had a similar situation many years ago. An operator with only a dozen or two jobs under his belt was rushed out to a residential wall by a completely unprepared foreman. Muddy conditions with little access yet the guy had his concrete on the job before he realized he needed a pump. Operator drove in further than necessary so he had the last mixer hang around to pull him out. Driver was in a hurry to leave, bugging our new guy to move it along. Sucked the ball, pulled the outriggers, and tried to move. Down it went. Thank God no one hurt and no other damage. Let the man do his job! |

||

| pudg2 | 12-14-2017 | reply profile send pm notify |

|

So every time a operator screws up it's managements fault or the ACPA ? How about operators or so called operators take the phone out your hand and the earphones out your ear and pay attention to wtf you are doing , yes there are things that need to be done better in this industry , like a alarm if you try and adjust outriggers when boom is not in the rack , this should be mandatory and I say alarm because disabling a outrigger while a boom is unfolded is not a option because of needing to readjust during pours. This industry is not the crane industry so need to compare , we do not make 1/2 of what crane companies make , this is a industry problem that this industries fore fathers created and has not turned in the industries favor and most probably never will . But it is always at the operators discretion ( in our company) to not setup if it's unsafe or the operator does not feel comfortable. Pay attention guys , stop getting or being distracted , you are in charge of a large piece of heavy equipment and one move can easily kill or injure someone , is taking that phone call really that important ? |

||

| bisley57 | 12-14-2017 | reply profile send pm notify |

|

I have been a certified lunatic with the ACPA since 1985,and I know why i dont get invited to their booty parties. As far as management,I am sorry you were offended, but get real REMF |

||

| Farmer Joe | 12-14-2017 | reply profile send pm notify |

|

I’m not trying to say it wasn’t our former operator’s fault (quit not fired). Obviously it was. Just that he was sent into a hurried situation without enough experience to be able to brush off the people trying to push him. This latest episode made me wonder if this operator was also being hurried since he was most likely blocking traffic. Very few other trades and operators deal with time crunches the way we do. Others schedule in days or hours, frequently ours are in minutes. Get into a routine and stay in it whether you’re an hour early or all the concrete is there when you get there |

||

| gillrod 1 | 12-17-2017 | reply profile send pm notify |

|

farmer joe is exactly right the one thing I have learned and try to drill into trainees is get a routine and stick to it. I have caught myself about to make a mistake while moving and it was always caused by someone trying to talk to me or rush me. you are in charge, do it your way . |

||

| pudg2 | 12-20-2017 | reply profile send pm notify |

|

Farmer joe , I had a seasoned guy of more than 30 years in the industry do the same thing , luckily no one was injured but the piece of equipment was a total loss , mistakes happen and they're honest mistakes , no one goes out saying I'm going to flip a pump today , but there's a guy that thinks everything is managements or the ACPAs fault , it's hilarious to me . The ACPA wasn't there , management wasn't there hurrying this operator , it was his (the operators) getting out of routine and trying to hurry that maybe was pushed by jobsite situations that was the end cause of this accident . In the end it was a unfortunate accident that thankfully no one was hurt or killed . Until manufacturers start putting safety mechanisms on these machines where a boom cannot be unfolded with out outriggers deployed or outriggers picked up why the boom is deployed these human errors will continue to happen. And for the record I've never been invited to a ACPA cocktail party or booty dance I think it was called. |

||

| LAGUS | 12-30-2017 | reply profile send pm notify |

|

I thought in America all pumps are equipped with safety features to prevent this ???? At least in Europe they are ! |

||

.jpg)

.gif)

.jpg)

.jpg)