| MVCP | 01-13-2012 | comment profile send pm notify |

|

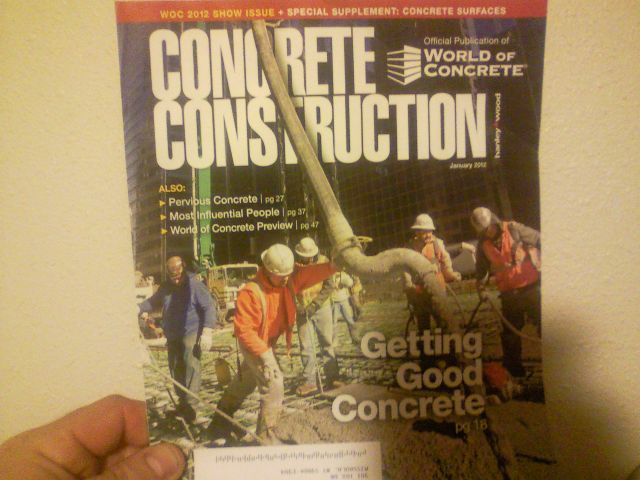

Hi All, I've had requests for a S tube on the end of my placement hose doing ICF walls and then explain the dangers. Its someting I wont do but I understand why they want it to slow down flow. Why would you use one for what appears to be a large slab. And again dangerous and something that shouldn't make cover page. |

||

| Vasa | 01-14-2012 | reply profile send pm notify |

|

I have them in the end of the boom...

|

||

| Seed | 01-14-2012 | reply profile send pm notify |

|

Good point Vasa! I cantb believe they put that on the cover! |

||

| SUPERDOFFER | 01-14-2012 | reply profile send pm notify |

|

I think todd have a job to do he is always promoting the world of concrete. |

||

| mile mark 96 | 01-14-2012 | reply profile send pm notify |

|

A good example of the dumb asses we have in the management end of our business |

||

| Deaner | 01-15-2012 | reply profile send pm notify |

|

i used to use these for ICF walls but i stopped doing it because of the dangers. I switched to a 2 1/2" whip hose instead. We usually use a 10mm (3/8") mix at about 28Mpa and a 5-6"slump[. Works really well but i know everyone worries about blockages with that small of a whip hose so i have a piece of 2x2" Steel mesh that fits over the grate in my hopper, keeps all the crap out and help the pour go nice and smooth! |

||

| Todd | 01-15-2012 | reply profile send pm notify |

|

I am a member of the ACPA and this is the email I got about this cover. Many of you may have seen the January edition of Concrete Construction magazine that prominently displays a double “S” device on the end of the concrete delivery hose. If not, you can view the digital link at http://www.concreteconstruction.net/table-of-contents/magazine.aspx. Although contractors may request these types of devices to prevent the “free falling” of concrete, they also weigh too much and become dangerous. Should the hose move unexpectedly, these devices could cause a deadly injury to the person directing the concrete hose or to nearby workers. For this reason, the ACPA does not recommend the use of double “S” devices. For more detailed information, please refer to the ACPA safety bulletin “Double “S” Bends Can Be Deadly” on the ACPA website www.concretepumpers.com. While you’re there, take a look at the hose whipping video. Can you imagine the injury one of those devices would cause if the hose whipped and hit a worker? Scary. Safe pumping! Christi Collins Executive Director American Concrete Pumping Association Ph 614.431.5618 Fax 614.431.6944

|

||

| Dipstick | 01-15-2012 | reply profile send pm notify |

|

I know its a lost battle but I would still like to see a discusion about wheter its dangerous or not with an S-tube. Let me start by saying that the disign on this cover is wrong. Its made of 2 90 degrees bends which is totaly unnessesary. 2 45 degrees bends do the job just fine and cause much less danger. And if the weight is the problem.. We just got in some great looking double 45's made of soft gummy. Super light and flexible. Got them in 5 and 4 inch. I like those very good and in my opinion they should be alowed. The argument of the sudden movement of the hose seems a bit overreacted to me. If we start thinking like that then a lot of machines should be wrapped in gummy. What about person lifts? They often work on head hight and can make sudden moves. What about all cranes? When they make sudden moves their loads start swinging to.. A forkilift driver can also kill someone if he drives like an idiot. Just as an excavator driver. That's the way it is when you control heavy equipment. You have to drive nice and slow and the owner should make sure he puts someone on the machine that knows what he's doing. The people around the machine should keep aware of what the machine is doing. I'm gona be slaughtered here but ok.. I've been driving with a doulbe 45 on my hose now for the last 4 years every single job. Its not my choise but I have to. The boss and the customers want it that way and I've tried to change it but I could not winn it.. Its that way or the highway.. I'm sure very few here have done just as many jobs with a S-tube than me so I should know shouldn't I ?? I never had ANY dangerous situation ever. Not even a slightly exiting situation. The weight of the S-tube actualy helps to keep the hose hang more stable. A hose without any steel at the end whips much much more and can just as well kill someone when it hit him in an unlucky way. So my vote is: The Double 45 made of soft gummy should be alowed. We could even make some solution with some rubber that covers the steel coupling needed to conect the S-tube.

|

||

| pumpjockey | 01-15-2012 | reply profile send pm notify |

|

We're not talking about the 'sudden movement' of the hose being caused by the operator moving the boom and the hose kncking the man off his feet. It's when a plug occurs in the hose or attachment and there is air trapped behind the plug, and the plug releases with EXPLOSIVE FORCE. You get a slug of concrete maybe 50 - 300 lbs or so (22 - 130 kg?) being propelled by a volume of air at up to 800 psi (5500 KPA) The concrete coming out is like the buckshot from a shotgun shell, and the uncontrolled recoil of the hose and attachment is like a baseball bat to the head or body, if not worse!! Remember your highschool physics - for every action, there is an equal and opposite reaction. There is TREMENDOUS power stored in that compressed air, and it's just waiting to be released, what happens when it does is up to you. But you're the guy with the remote in hand, away from the worst of the resultant action. (unless you also are the hoseman, which is another safety issue altogether) The hoseman may not be aware of the danger, his wife sure isn't but she may find out, his kids will never understand, and his doctors, nurses, nuerologists and plastic surgeons are merely dealing with the aftermath, at best, at worst, it's another customer for the funeral home. Whether the 'S' is made of steel or a 'gummy material' as you said makes little difference, as a pumper, you know full well that plugs are much more likely in elbows than straight sections.

The floor is now yours to make a good argument (try to make it so the victim's kids understand it, please) |

||

| mile mark 96 | 01-15-2012 | reply profile send pm notify |

|

Until fines and or jail time are issued when operators knowingly do something "wrong" ,nothing will change. |

||

| Dipstick | 01-15-2012 | reply profile send pm notify |

|

You are right Pumpjockey. That force is indeed extreem. I have experianced that once myself. I was blown 3 meters through the air by a hosewip. I still remember the insane force I felt. I must admit you have a good point there.Not saing I'm doing the right thing now. Like I said I have tryed to change. I ordered a pin pour and wanted to start using it but they didn't give me a chance. Orders from the highest level say NO.. But the double 45 is very unlikely to plugg in comparisment to this idiotic double 90. Besides a lot of operators like to reduce just off the boom and put a thinner endhose on. What if this plugg and release thing happens up in the reducer with air trapped behind? It will give that thin hose a super hosewhip. Ok.. then there is no steal at the end so thats good but with my rubber double 90 there's not eighter.. And there is a much bigger chance for a plugg in a reducer than in a 5'' double 45 it my opinion.

|

||

| pumpjockey | 01-15-2012 | reply profile send pm notify |

|

You connect the rubber double 45 with a hose clamp?

Of any of the homemade anti-splatter contraptions, I like Kris Leers idea of the traffic cone on the end of a single ended hose with no steel holding it on.

Here's a link: www.youtu.be/p-iiNcn6mQ |

||

| pumpjockey | 01-15-2012 | reply profile send pm notify |

|

Sorry, the link is: www.youtu.be/p-iiN_cn6mQ (I use Google Chrome for a browzer, and I can't copy and paste into this forum. So I have totype it in manually - any little error in syntax and it fouls it up) |

||

| Dipstick | 01-15-2012 | reply profile send pm notify |

|

And about what I've been doing the last 4 years with the steel S-tube.. I could have refused but than I would have another job now and some other guy would do it instead of me. Maybe I'd then rather do it myself so I know I pay attention and do everything to ensure the safety of the hosemen. It is possible to see when it pluggs in the S-tube you know.. The flow will stop... And as long as you are not pumping like crazy you will have time to shut off the pump before it explodes.. Its just all about eyes on the endhose and one finger at the pumpswitch all the time.. |

||

| Dipstick | 01-15-2012 | reply profile send pm notify |

|

And I like the traffic cone to.. I would love to try but again... I have no say in this.. |

||

| Todd | 01-16-2012 | reply profile send pm notify |

|

I have been told that some states will not let you pump bridge jobs with out double 90's. It's written in the spec. |

||

| pink panther | 01-16-2012 | reply profile send pm notify |

|

My answer is. " I do have a double 90, it is just above the tip hose." Plus I run pump in Z formation most of the time which helps also. |

||

| SUPERDOFFER | 01-16-2012 | reply profile send pm notify |

|

Dipstick you have to play it smarter. you know whe also have that double 45 on the pump, but since I have told the boss the slab crews don't want a double ender any more. my pump is changed to a real tip hose. And because of that the double 45 don't fit anymore. Yes I may not refuse to use it if the costumer ask for it but then first we have to change hose and that costs time. So most costumers then say leave it. |

||

| Dipstick | 01-16-2012 | reply profile send pm notify |

|

Most customers here will say.. Do it. They are adicted to the S tube. For some people its very hard to change something that they've been doing all their life you know. Honestly I've tried it here. I had pinpour and endhose ready for use but I had to take it off the truck again. Even my big mouth could not make a difference |

||

| Beast | 01-18-2012 | reply profile send pm notify |

|

Dipstick, I feel for you , its not a matter of if , its when someone gets hurt they will change their minds,i worked for a company it was common place to use them I refused , took them off my pump, I would however put a metal reducer and a 4" whip hose to accomodate the customer , this always worked for me, then one day a hosemans leg was broken, compound fracture , needless to say double 90s on the end was a thing of the past, had a few out of town guys that would still use until customers started requesting them and their double 90s, after a few days off they began to see it the owners way, when it cost him thousands in lawyer fees and medical bills I promise you he will change. |

||

| Travelteck | 01-18-2012 | reply profile send pm notify |

|

Todd Don’t you have that video of the tip hose exploding from a plug releasing? The s-bend issue is also partly concerning this. One of my concerns was commented on in this post with contractors “demanding unsafe practices” on sites. Just because Old unsafe practices are “grandfathered” into working practices that even MFG’s don’t allow anymore I don’t under stand how they can force this into job site practice, but it seams from this they still do. I have even seen it my self. I have been on jobs where you spend a full day in safety orientation just to get onto the site, and then the contractor forces the customer to do something with the pump that’s not allowed. I am not trying to stir stuff up, but with all the I phones out there if the guy had a short Video on their phones they could show a contractor of that tip hose blowing it might open some eyes. What do you guys think.?

|

||

| Dipstick | 01-18-2012 | reply profile send pm notify |

|

Its the same here. Norways bigest buildingcompany is all about safety. You can not fart or you have to give it an orange jacket and a helmet.. Everything has to be perfect. They know the S-tube is forbiden, I sugested to try other things like the pinn poor but they insisted to use the S-tube.. On every kind of job that is. Also on 1000 yards slabs etc.. |

||

| Todd | 01-19-2012 | reply profile send pm notify |

|

Here it is. I think the ACPA did this test. ACPA rocks. http://video.concretepumping.com/videos/852/hose-whip |

||

| Dipstick | 01-19-2012 | reply profile send pm notify |

|

The effect is all in the way the hose is hanging. If the hoseman has the hose on his shoulder pushing it in a strong angle it will wipp much harder.. Maybe they should do the test with a dummy man. It would show the destructive force quite good I think.. |

||

| Pumpkiller | 02-13-2012 | reply profile send pm notify |

|

We use 4 inch "double 90s" or quad 45s on our residential wall pours. No issues,any good operator knows when he/she has a plug before hand. If your pumping at a steady pace,be it fast or slow,as soon as the pump changes it's rhythm,concrete stops coming out or other,you stop the pump and investigate BEFORE something happens. |

||

.jpg)

.gif)

.jpg)

.jpg)