| Travelteck | 10-13-2012 | comment profile send pm notify |

|

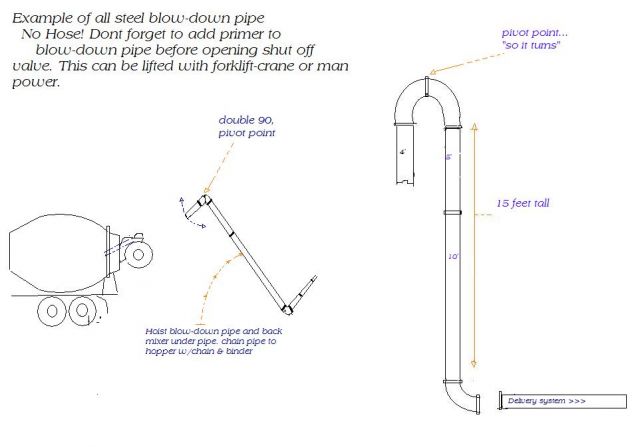

OK Guys I have a request. There is not a lot of pics of placing boom systems. I wonder if I could get a few pics of Blow out stands you have made up. They are quite simply a form of Art that is unique to Placing boom and high rise pumper’s. When I get questions as how they should build one I do not have a lot of visual references to show customers. This is a Mock up display we did for a Con-Agg show. Can you help me ? |

||

| dazzle | 10-13-2012 | reply profile send pm notify |

|

dual pipe line blow out stand |

||

| putzman1975 | 10-13-2012 | reply profile send pm notify |

|

your missing concrete block built on pipe line to keep it from moving 6x6 box one on pipe line and one on blow back. |

||

| dazzle | 10-13-2012 | reply profile send pm notify |

|

like this? |

||

| dazzle | 10-13-2012 | reply profile send pm notify |

|

and we use these instead of block |

||

| Dont need one | 10-13-2012 | reply profile send pm notify |

|

I will see if I can find you some pictures. Your first picture I didnt like with the 45 dgree elbow attached to the hose. It would be to hard to get into mixer unless it was 16' tall, and you dont want a lot of hose outside of mixer because if you have a problem to much hose outside could become like a fire hose with nobdy hanging on to the end. Same picture you want a 9' or 10' hose to get far enough into mixer so splash back dosnt occur. When the concrete hits upper fins on drum it can splash back out of mixer and make a mess. Didnt see any way to chain stand pipe assembly to mixer, this is a safety issue, PERIOD. I didnt like the second picture either but if it works for them ok. Metal brackets to hold up the stand pipe are ok, I like to use about a 24" elbow on bottom and top with a makeup pipe to get the height about 6" to 12" inchs above mixer hopper height. I forgot encase bottom elbow in about 3'x3'x3' concrete block of concrete. Back your truck in close enough, stop the truck, push the hose on top of the hopper of mixer. While standing on platform back truck in while feeding hose into hopper. make sure about 7' of 10' of hose is in mixer and stop mixer. Chain top elbow and hose to mixer and pull mixer forward to tighten up chain. You should use at least a 185 CFM compressor. prior to this depending on how high or how far you are blowing back you should have wet up your blowback. You dont have to use full air, you need to learn to listen how fast the mud is moving. You can turn the air down so the impact into the mixer isnt to bad. I hope this helps and I will look for some pictures. |

||

| TooTall | 10-14-2012 | reply profile send pm notify |

|

|

||

| Travelteck | 10-14-2012 | reply profile send pm notify |

|

Thanks for the help on this, the pics are great for reference. Like I said before there are as many different ways to do these as there are job sites and different circumstances. And Yes if a mixer is used the system needs to be secured so it cannot come out of the mixer. Fact is the entire pipeline placing system needs to be secured. Some are also using crane buckets and recycle bins. Also as I said in the first post, the Pic I posted was a non working mock up for show only Thrust blocks are also a site unique and specific kind of thing. Lets see them as well. Thanks again for joining in.

|

||

| Dipstick | 10-15-2012 | reply profile send pm notify |

|

This is the kind of subjects that make me want to hang around here |

||

| Doug | 10-15-2012 | reply profile send pm notify |

|

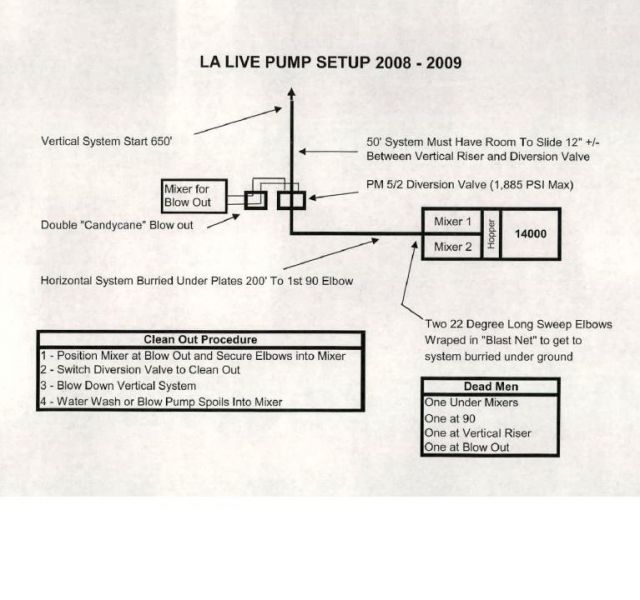

I can't believe I never took any pics of this but here's our set up diagram.

|

||

| Travelteck | 10-15-2012 | reply profile send pm notify |

|

I am having the same Duh moment, all the setups I have seen and very few Pics |

||

| TooTall | 10-15-2012 | reply profile send pm notify |

|

Sorry TT.. There just aint much time to take pictures when its time for blow down! |

||

| Dont need one | 10-15-2012 | reply profile send pm notify |

|

Travel Tech sorry I cant find a picture, if I do I will send it to you, and I forgot the prime port just above the lower elbow incased in concrete. Its very simple and they dont have to buy anything new as long as thier elbows ect. are in decent shape. |

||

| dazzle | 10-17-2012 | reply profile send pm notify |

|

all said and done water wash is the way to go these days any way. alot safer and get to use most of the crete. have personaly done a 54 story building this way, just not sure how high you can go, any one done higher? |

||

| Dipstick | 10-17-2012 | reply profile send pm notify |

|

Quite sure a lot of people will disagree with that. Water wash is a less safe method. But let's just axcept that there are different opinions about water wash. |

||

| rusty22 | 10-18-2012 | reply profile send pm notify |

|

Try sucking the ball back,works fine.And you have more control.Put a priming port next to diversion valve going to mixer. |

||

| TooTall | 10-18-2012 | reply profile send pm notify |

|

Water Washing a placing boom system!?!? I'd like to see that mess.. Ive sucked a ball in an emergency and that was waaay more mess than I care to have to deal with. |

||

| rusty22 | 10-19-2012 | reply profile send pm notify |

|

To Tall How is sucking a ball back messy.Unless you don't have a Diversion valve.You suck it back fill the hopper switch the valve,pump into mixer,switch back valve suck back fill hopper,ETC ETC |

||

| Doug | 10-19-2012 | reply profile send pm notify |

|

I can't see us sucking back a ball from 700' vertical with horizontal system on top. |

||

| rusty22 | 10-19-2012 | reply profile send pm notify |

|

How about 870' It's no differant than a trailor pump with 200'laid out on the ground.Put the ball in and suck it back. |

||

| Dipstick | 10-19-2012 | reply profile send pm notify |

|

The vertical pipe will actualy help you suck back since the concrete will like to go down quite much |

||

| dazzle | 10-20-2012 | reply profile send pm notify |

|

too tall . thats the idea of water washing a placing boom system No Mess water recycled, concrete used in job, all but last .2 of a meter |

||

Thanks Traveltech.

Thanks Traveltech.

But you can always help it a bit by pushing with air from the end..

But you can always help it a bit by pushing with air from the end..

.jpg)

.gif)

.jpg)

.jpg)