| Travelteck | 02-13-2010 | comment profile send pm notify |

|

Ok Fellow pump enthusiasts time for a little pump maintenance. When I get the call that my pump won’t pump or clear the E-Stop it is generally followed with an expletive comment about electrical nightmare. I wish to help you out. How long have you been running the unit? Most likely Years. Like all the mechanical aspects of your pump the electrical system needs Maintenance as well. Now don’t be afraid it’s not that bad. Keeping the system clean and tight will help a lot to AVOID electrical issues. Start in the Cabin. Is the Alternator putting out? If the truck power supply is low how can you expect the pump to function correctly, Alternators WEAR OUT and they can stop completely or just loose performance and not put out enough. Just because the Truck started is not a good enough test, Test the output voltage at the alternator. It should be at least 13.6 VDC On US and Canada units, International units might be operating on a 24 VCD system the principles of Maintenance still apply to you the same way. Checking for clean and tight battery connections and GROUND connections is a good start, Growing Green Fuzzies at the battery terminals are a common issue in pump operation issues from E-Stop to Remote performance. So check it out, How old are the batteries, bad batteries or worn out ones cause the unit to operate low on voltage due to lack of AMP’s available so a Battery load test is a good thing to do. Clean and check them. “How do these connections get loose I haven’t touched them”? As current flows threw connections heat is created this causes expansion and contraction that can make the connection loose over time and this causes more heat and it just get’s worse. An easy fix is to clean and tighten the connections. MOST ELECTRICAL ISSUES CAN BE TRACED BACK TO NEGLECT. I am not talking about ripping out the entire system and rewiring it, but checking the main power connections can save you a lot of hair pulling Take a little time to check it out, don’t take the opinion that its working I don’t want to mess with it, just start slow and easy checking the battery connections and ensuring the Alternator is up to speed are basic truck Maintenance, it can save thousands of $$$ when you are on a pour and the “Expletive” is messed up. If you are not sure ask the local Parts store How to test the As always the Customer support group is there to help answer questions. Use the tool available to you. All Mfg’s are motivated to helping you keep your unit operating. I will also be available to help if you have specific Putz questions. 800 890 0269 is the Main contact # 24/7 woodsa@putzam is my e-mail 360 600 5695 Cell Keep it safe and learn something new every day. Keep in mind there are no Stupid questions, just expensive issues due to lack of understanding. |

||

| IsaacG | 02-13-2010 | reply profile send pm notify |

|

Alan, you like to make people work. Here's the conversation with me. E-stops don't work. Pilz relay, 13 to 14, 22 to 23, 33 to 34, and remove wire 42. E-stops clear and no functions? Plug in the hardwire. Still no functions although e-stops cleared, hook up the jumper cables and finish the job. No power back there at all, get on your back and the only two electrical wires at the PTO box, cut them and tie 'em together. You got mud in the boom, no time to jack the cab and fix this stuff right. When are you coming up to seattle next anyways? |

||

| IsaacG | 02-13-2010 | reply profile send pm notify |

|

Almost forgot about that pain in the ass (albeit necessary) hopper grate safety switch. X10 (the long terminal with all the wires on it bottom left of control panel) pull out wires 152 and 153 and hook up a little jumper to finish the job. There you go, 75% of Putz electrical problems in 5 minutes or less. I know the mercury switches are a pain in the ass too, but I haven't memorized those yet. I think you just jump the line across the pilz relay that are normally closed and break when energized (not the e-stop relay but the double-red ones) |

||

| Travelteck | 02-13-2010 | reply profile send pm notify |

|

Issac lets talk 360 600 5695 |

||

| eugene | 02-13-2010 | reply profile send pm notify |

|

all i want to know is the hopper grate by pass on my 2006 thom katt, lots of conections so can you remove that harness and do you have to use jumpers to make the pump run. brian |

||

| Travelteck | 02-13-2010 | reply profile send pm notify |

|

If you check my profile I am a factory Rep, so I can not tell you how to bypass a safety switch. Nor do I want to But, Is it not working? The switch is there to protect the personnel who operate the unit not just yourself. The industry has lots of examples of bypassing safety stuff and the Lawyers salivate at the prospect of tearing the person apart that did the bypass. With that said it can be repaired and its not that hard. If people spent as much time learning the system to fix it as they do trying to get around or bypass it the industry would be a lot safer. I am willing to talk to you about repairing the system to make it function and be safe. I would be willing to bet the conversation to fix it will be easier than bypassing it. |

||

| eugene | 02-13-2010 | reply profile send pm notify |

|

knew i would get my tit in a ringer but it was if that line got damaged as to provide a false dead circuit, would you need a bypass to operate the machine. ps kinda wish that i did not have the remixer as to add to safety and a more basic unit. |

||

| Travelteck | 02-13-2010 | reply profile send pm notify |

|

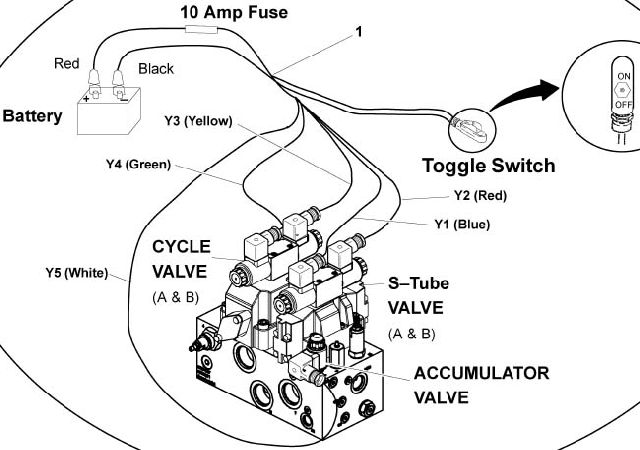

Your proverbial Tit is not in the ringer…. yet, like I have said there is no such thing as a stupid question. I have a question for you and all Tom Katt owner/operators. Do you have an Emergency Stroke change kit? It would connect to any 12VDC source and connect to the coils to operate the pump if the electrical system has a failure; if this is with you and you have connected it in the past “for practice” not fun to learn when the concrete is setting in the system. It will get you out of a bind. It will be discussed in your manual you can purchase one or build one for yourself they are simple. Alligator clips, in line fuse 7 AMP, Extension cord, 5 Plugs for the coil’s and a toggle switch will Git er done. E-Mail me and I can get you a drawing if you need. |

||

| Todd | 02-13-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 02-13-2010 | reply profile send pm notify |

|

Thanks Todd. See why it is always good to check the manual I got the fuse wrong. |

||

| Boom Inspector | 02-13-2010 | reply profile send pm notify |

|

This is what this site needs more of in regards to safety/maintenance and general helpful tips for everyday operations. This was an excellent article and then Todd added the picture and bam we got us a helpful tutorial !! Nicely done Alan |

||

| bigpumpb | 02-14-2010 | reply profile send pm notify |

|

wow thanks alan and todd. its about time to see some great info instead of all the bashing .this helped me out thanks again great job. |

||

| northwest63 | 02-14-2010 | reply profile send pm notify |

|

travelteck,-Thanks for stoping by.woking the bug's out ,the new parts shoud be here soon and we have ordered moor sweep!!! LOL...I have not got the pic of us yet? |

||

| tebequip | 02-16-2010 | reply profile send pm notify |

|

Awesome. Great stuff from the tech and Putzmeister.

|

||

| hammah | 02-16-2010 | reply profile send pm notify |

|

Todd did you forget the video of that? lol

http://video.concretepumping.com/video/702/Putzmeister-Manual-Stroking |

||

| Boom Inspector | 02-16-2010 | reply profile send pm notify |

|

well Hammah that was a good find and explained it better in video than words can explain.. |

||

| b-alto | 02-17-2010 | reply profile send pm notify |

|

I have one thing to say about electrical maintenance. Don't break off the lug holding the large hot wire connecting to the alternator.I did it last fall a half hour before a pump job. The connection was corroded so I had some time tried to take the wire off. Spun the inner lug till it broke off inside WTF. So I brought a battery charger, had to drive 65 miles, stopped at a RM plant and charged for a while then charged while pumping. I pumped two jobs that day with no alternator. On the way home it was getting dark and my head lights were very dim. |

||

.jpg)

.gif)

.jpg)

.jpg)