| Travelteck | 03-01-2010 | comment profile send pm notify |

|

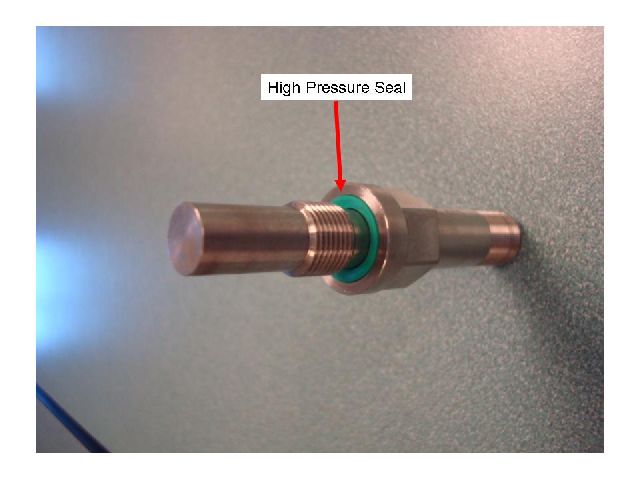

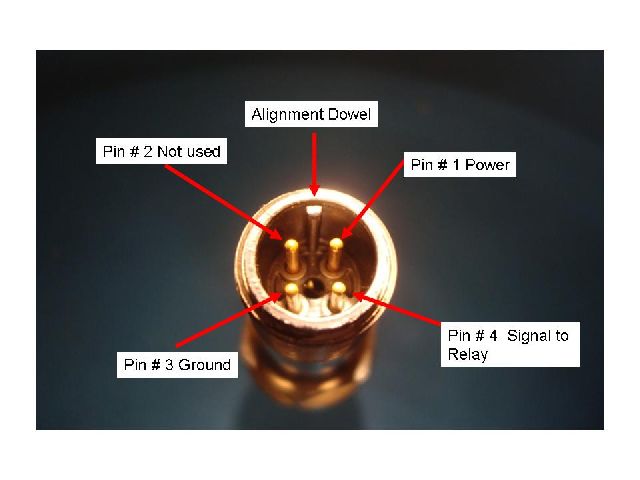

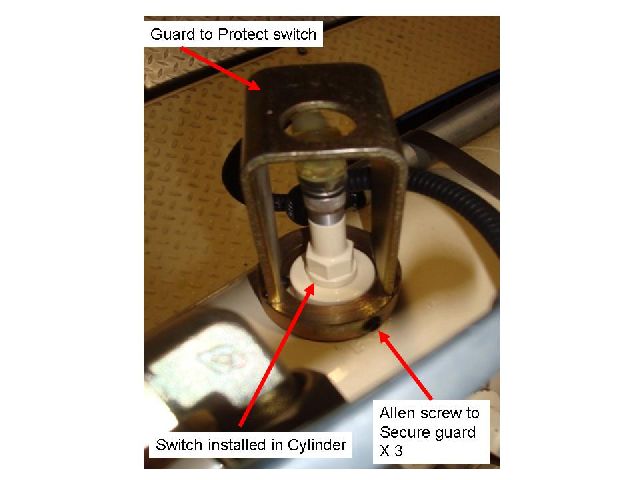

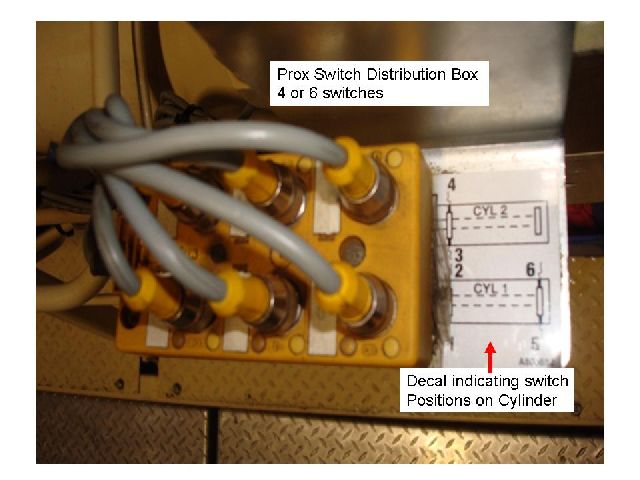

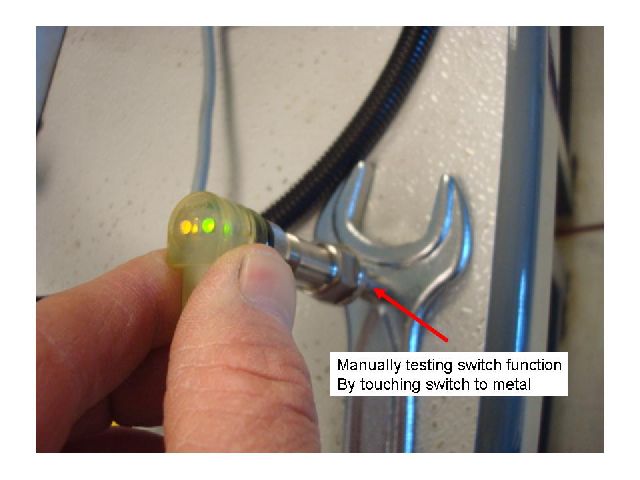

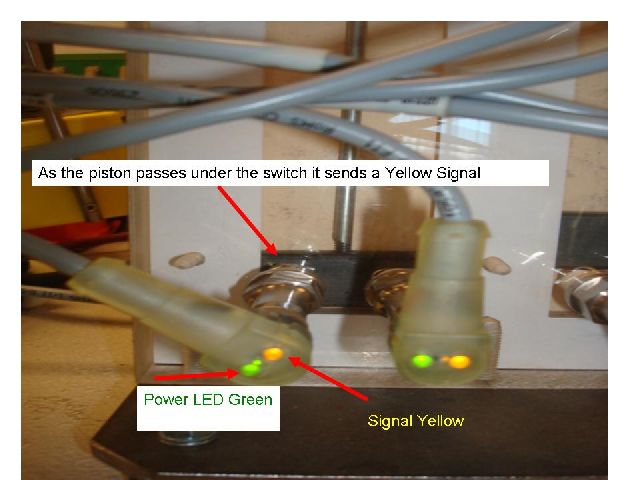

Proximity Switches: Your Putzmeister uses proximity switches “aka Prox switch” to cycle the pump. Some quick tips to keep them from being a misunderstood item on your pump. Prox switches are screwed directly in to the drive cylinders; they are subject to High pressure hydraulic oil. It is common to over tighten them, they take 14 Foot pounds of torque, this is a relatively low torque, because they are in the pump hydraulic cylinder subject to high pressure oil they are quite often Over Torqued , this distorts the switch and it will fail early or not work correctly. They have a high pressure seal to handle the pressure subjected to them. Next prox switches are grounded threw the cable not the cylinder, so to test the system you can take a new switch in your hand plug it in and touch it to metal and it will trigger. The switch works from magnetic principle, the piston is steel and the switch is triggered by this steel piston passing under it. On top of the plug you will see 2 Led’s one is green and one is yellow, The green one indicates that power is getting to the Switch, the yellow one is the trigger signal that is indicating the piston is under the switch sending a signal to the relay. The prox switch wires go back to the distribution box, this box combines the signal to send it to the stroke change relay, Led’s are located at this box to tell you if they are working, you might have 4 or 6 switches on the standard units. We encourage you to watch the lights when you are cycling the unit to clean the water box, you should see the yellow led’s flash when the piston is passing under the switch, you have 2 switches at each position. They are working together as a back up, this means if one fails you are still pumping. Switches can generally fail 2 ways, no yellow Led when the piston passes under it, this is the most common failure, they can also fail stuck ON, Yellow Led on even though the piston is not under the switch, in the first case no action is necessary, but if the switch is stuck on it will need to be disconnected from the system as it will interfere with the cycling of the relay. Simply unplug the one that is failed ON, and resume pumping. We all know that if it can go wrong it most likely will, this is the reason for the redundant style system but quite often due to lack of maintenance or lack of understanding one switch will fail, then at some point in time the other switch beside it will fail now you have a problem. So familiarize yourself with the system and check it frequently, then you can avoid being down due to prox switch failure. The pics show a model I use in the class room to demonstrate the switches and the cylinder, position. As well as testing a switch not installed on a unit. Please ensure the truck is out of PTO and engine shut off before changing a Prox switch, the cylinder is charged to 34 Bar hydraulic pressure even with the pump not stroking. |

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

|

||

| biged | 03-01-2010 | reply profile send pm notify |

|

OLIN ball valve pumps use them also very dependable switches. |

||

| lawrence | 03-01-2010 | reply profile send pm notify |

|

A problem I had once with them once was because they are magnetic a metal flake stuck to one of the switches, the machine thoght the rod end was at both ends so the pump locked up. would not go foward or reverse. took out of pto but did not wait long enough for them to demagnatise, you have to wait atleast 5min for that to happen as i have been told. Got boom blown out and every thig clean but it was a bad morning. |

||

| Travelteck | 03-01-2010 | reply profile send pm notify |

|

Lawrence:

That is a good one and VERY possible.

I have had this happen to customers twice in 12 years, I can’t speak about the partials getting magnetized though. It is more likely they were floating around then hitting the switch just right.

I wish we had spoken or you called for help, Make sure your manual stroke change kit is on the pump and working, you could have finished the job.

If you need help with that you can call me: 360 600 5695

I can also e-mail the pages for using the kit. It was also on a post I did a while back.

Thanks for responding.

Alan

|

||

| mudcup | 03-02-2010 | reply profile send pm notify |

|

That was very informative I knew how they worked but I think that will help out new operators we all know what its like to be green on the pump very nerve wrecking.Thank great post. |

||

| pudg | 03-02-2010 | reply profile send pm notify |

|

I have some on a linepump with no leds how do you check those ? |

||

| biged | 03-02-2010 | reply profile send pm notify |

|

Pudg mine are under the lid on the wet box , take it off and place it beside you, then take anything metal turn on your stroke then use the peice of metal say a key and use that to stroke touch one then the other. |

||

| Travelteck | 03-02-2010 | reply profile send pm notify |

|

Pudg:

Depending on the vintage of your TK you can look in the control box, the K238 relay is mounted on a base that should have 2 Yellow LED’s, they are the input signal from the prox switches. On older units they are switching ground those have a K1 relay for switching.

If you private e-mail me your Ser # or post it either way I can check what vintage you have to be sure. Good question.

|

||

| toper | 03-02-2010 | reply profile send pm notify |

|

has any one told u ur a god sent, well if they havent , u are, i for one read all ur posts and am quite appreciative of it, these prox sensors are the same principle than olin uses on their line pumps for as thats were i started along time ago, putz just uses 2 extras for backup(genius) thanks again and keep em coming, (with pics please) as for ive only been on booms for 3yrs now and love learning as much as possible ;) |

||

| pumper chuck | 03-03-2010 | reply profile send pm notify |

|

my opinion on prox switches is that it is a waste of money and just another way to increase the price of a pump.why you need to know where the cylinder is and if at the end of a stroke is bs. one more electrical problem waiting to happen as if there isnt enough already. if you need to know where the cyl.. is open the water box lid. at $100.00 to $150.00 bucks a pop not to mention replaceing the wires a unnessasary expence . this is just my oppinion so dont be offended. for you prox lovers, love on. [ prox switchs $100.00 to $150.00 each] [wires & connectors $400.00] [switch box $$$$$] [computer componants $$$$$] [pump without prox's,,, priceless] |

||

| SUPERDOFFER | 03-03-2010 | reply profile send pm notify |

|

pumper chuck you must be a schwing man. but i can say hydrolic hoses are also expensive l.o.l. |

||

| txredman | 03-03-2010 | reply profile send pm notify |

|

Excellent article!! |

||

| Yuri | 03-04-2010 | reply profile send pm notify |

|

Yeah, the article is very useful!!! Big thanks! |

||

.jpg)

.gif)

.jpg)

.jpg)