| Travelteck | 02-12-2012 | comment profile send pm notify |

|

I posted this a while back and thought it might be good to run it again

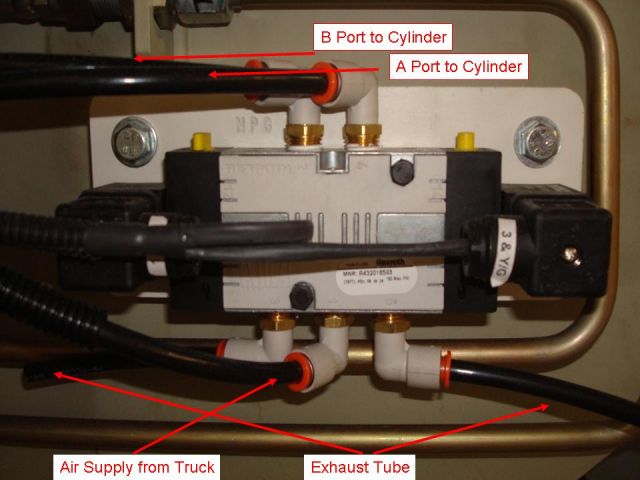

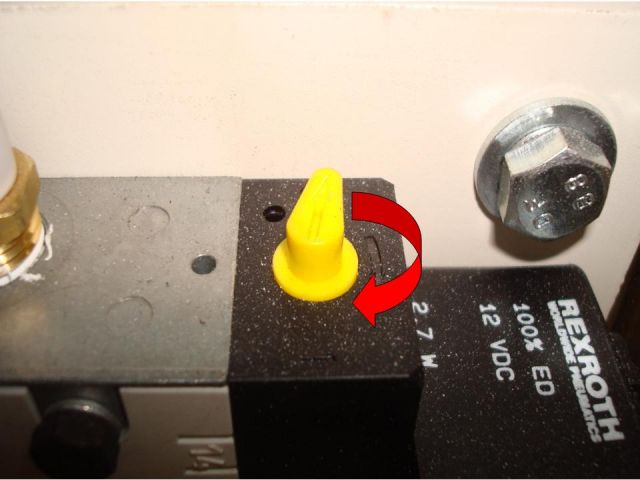

PTO air valve operation and repair. Do you know that you can put your Putzmeister into and out of PTO without electrical power? This is the Current production air valve, it operates just like the older one, It can be operated without electrical power, It has 2 twist buttons to operate the valve in and out of PTO No swapping air lines. If you need to switch from PTO to Drive or back unplug the coil power and you can operate the valve from the twist buttons. Turn 1 button and listen for the shift, then return the button to the ORIGONAL position, Then turn the 2nd button and listen for the shift, RETURN the button to the original position. IT IS VERY IMPORTANT TO MAINTAIN ALL PLUGS, COILS, BUTTONS AND AIR HOSES BACK TO ORIGONAL POSITIONS, confusing these things can lead to the Pump/drive switch to not function correctly. The older style has buttons that can be operated with a small screw driver buy pushing in and twisting. On both styles it is Important to “unplug the Power at both coils.”

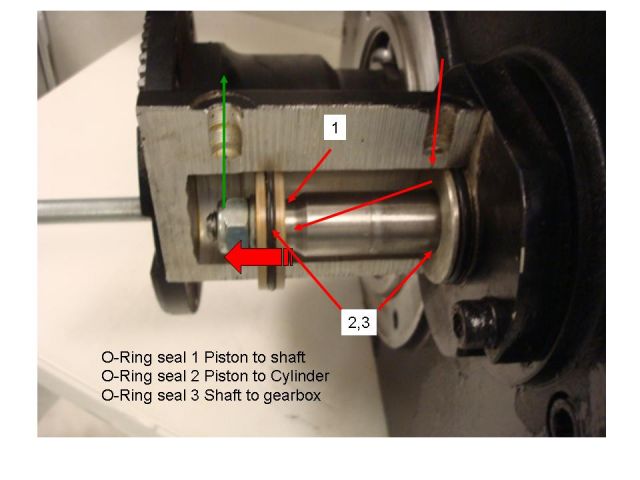

If you have air exhausting threw the exhaust tubes it is most likely to be an issue in the cylinder not a defective air valve. This can be tested buy using shop air no more than 100 PSI and a soft tip air nozzle to shift the cylinder back and forth. Mark for location and remove both lines at the air cylinder and use the shop air to shift the cylinder if air is leaking past the piston you do not need a air valve, you need to service the cylinder. O ring’s seal the piston to the shaft under the lock Nut as well as Square quad ring that seals the piston to cylinder. Also the Lock Nut can work loose ESPECIALY if it was rebuilt and the old Lock nut was reused. Another O ring seals the rod to the gearbox so if air is leaking out of the gear box breather look there.

The Key to all this is to learn how it works, Please FIND the Air shift valve on your truck and test it for manual operation, It might be buried under concrete and grease, finding and learning how to use the backup features is best done in the shop, not on site with concrete getting hard, “That’s how most of us learn it”. There were some Putz’s that had this valve located under the frame above the Transmission. Please don’t get under the truck with the engine running or the driveline spinning. If this raises questions ……..Good, I would love calls or E-mails This is part of the things taught at the Putzmeister Service Training School, I know it is hard to get time to be gone from the job to attend but it might be well worth it to learn a little more about your pump. Alan Woods 360-600-5695 Putz Customer Support Group 800-890-0269

|

||

| Travelteck | 02-12-2012 | reply profile send pm notify |

|

|

||

| Travelteck | 02-12-2012 | reply profile send pm notify |

|

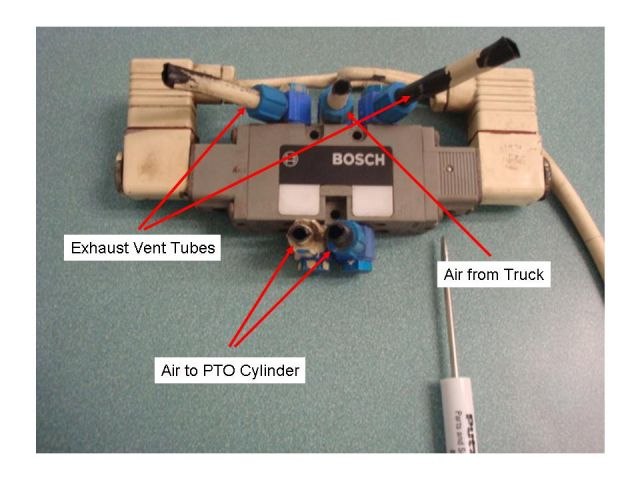

This is the Version used in the earlier models of Putzmeister Pumps, It is also able to Manualy operate |

||

| Travelteck | 02-12-2012 | reply profile send pm notify |

|

|

||

| Travelteck | 02-12-2012 | reply profile send pm notify |

|

Another thing to think about, If you are wearing out the O-Ring seals in the PTO Air cylinder often, Please check the driveline from the Trans to the PTO if it looses balance it will vibrate and the Aluminum cylinder, Piston and O-Ring take a bunch of wear, if this is the case the Cylinder and Piston might also be worn so as not to hold a seal. Getting the Drivelines balanced is often overlooked and can cause a lot of expensive repairs to be needed |

||

| Pumpkiller | 02-13-2012 | reply profile send pm notify |

|

This is good to know,went to the service school back in 2000 and don't remember Dave showing us that |

||

.jpg)

.gif)

.jpg)

.jpg)