| Todd | 04-03-2011 | comment profile send pm notify |

|

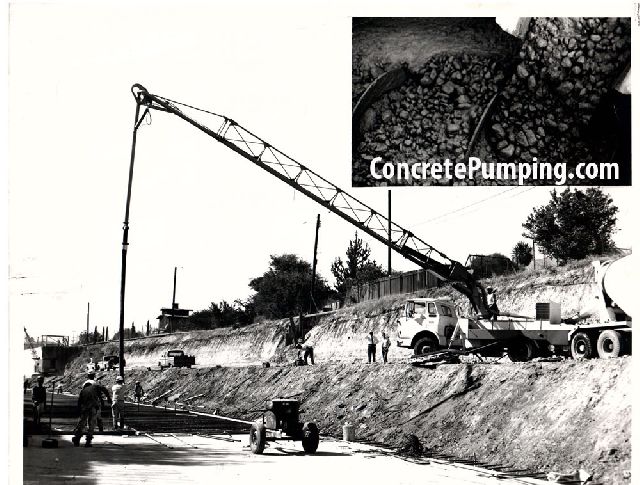

Date 7-2-1970 5" Boom Pipe monted ona 740C GMC Diesol. Gerneral Contractor is Steve P. Rados Inc. Pumping Contractor is Steve Merli Location Canoga Park Mix-Standard LA County Flood Control Mix (Unpumpable through 4" boom) 11/2" rock. Unloading 5 cubic yards in 5 minutes (96 Cubic yards per hour at 500 PSI

|

||

| Todd | 04-03-2011 | reply profile send pm notify |

|

Here is another photo of a different pump |

||

| Many | 04-04-2011 | reply profile send pm notify |

|

Wow,that's bringing back headaches.Those were visionaries back then,pumps not reliable,mixes were non-existant.Trying to sell there services with mixes that didn't belong.Ahhh,those were the days,now one needs to be a chemist.It indeed was a tough sell!!! |

||

| pump031 | 04-04-2011 | reply profile send pm notify |

|

Wow great stuff, I bet he was getting big money too! |

||

| Mudslinger | 04-04-2011 | reply profile send pm notify |

|

Younger operators wouldn't believe how hard being an operator was in the old days. Yes, I know, 5 miles in the snow, uphill both ways! My first pump was just like the one on the bottom, and it was a beast! If you plugged up on an uphill pour,you were either gonna have to empty the hopper, or the mud on the uphill was gonna come down the hill! And with the old mixes, you could plug up 10 times in a pour! EASY! Sure, there were things you could do to slow things down, but you were gonna make a mess, and, you were expected to clean it up!!

Then the booms started coming around! ALL swivel joints were RUBBER hoses! And we called them hard hoses, because they had to be hard enough to not collapse when you reversed the pump. Outriggers were unfolded by hand, a strut rod pinned to the frame (see photo #1), and then you chained the AXLES to the frame to make everything rigid. Then you could power the outriggers down.

Cleanout was also a skilled event. For articulating booms you rolled up a paper wad, shoved it up the tip hose, put on a water cap with a one-way valve, put about 10 gallons of water in, then stood the tip up, while slowly stroking in reverse! Stick booms (both pics) you shoved a TIGHT wad of paper in at the pump side and used your water to push it out the other end. Smart guys raised the boom about 10 feet, then you could get most of the water back by unhooking the water hose from the water pump and putting it back into the water tank. Air was rarely an option because we only had hydraulic brakes!

Today begins my 38th year of running a pump! When I hear young guys say how hard they work, I'd like to take them back to my early days. You just don't know! Pumping concrete is ONLY hard when it's hard! Today was easy!

Now let me tell you what I know about running a pump! Concrete in! If all goes well, concrete out! Everything else changes! Figure it out as it comes along! When all else fails, panic! Misery LOVES company! The longer you do this job, the less you know! Somewhere, somebody always has an easier way! Don't be afraid to steal a good idea! Have fun, or this could turn out to be a real job! |

||

.jpg)

.gif)

.jpg)

.jpg)